Material available for FDM

Our 3D printers allow us to quickly swap materials in their workspace. This allows us to deliver your prototype in a short amount of time, starting from a single piece, using material that will perfectly match your needs.

You do not have to worry about choosing the right material for your prototype. We will do it for you! All you have to do is attach a file with the Technical Data Sheet (TDS) of the material you want your final product to be made of or let us know what environmental conditions it has to withstand. We will select the material that will best reflect the characteristics you want.

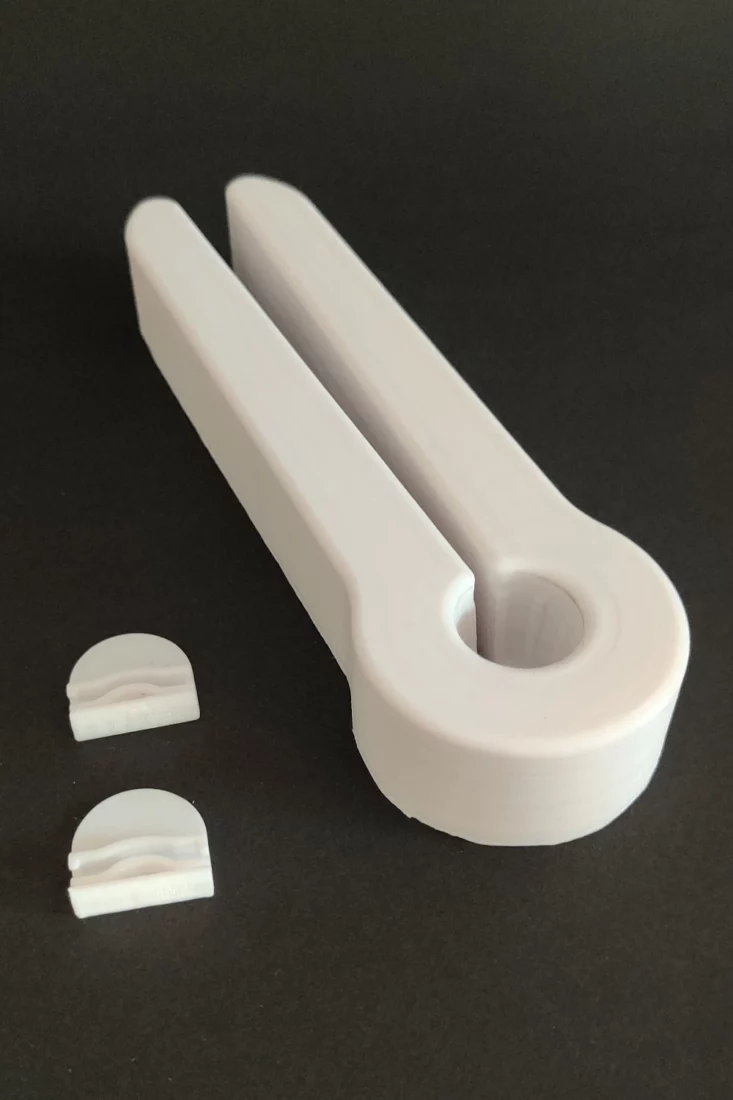

One of the most important advantages of FDM 3D printing is the variety of materials that make it possible to produce parts for a wide range of applications. You can choose from a wide range of filaments such as ABS ASA, PETG, PA, PC, PLA, TPU, Ultem, etc. PA Filament can be filled with secondary materials such as CF (Carbon Fiber) or GF (Glass Fiber) to increase its mechanical properties such as tensile strength or impact resistance.

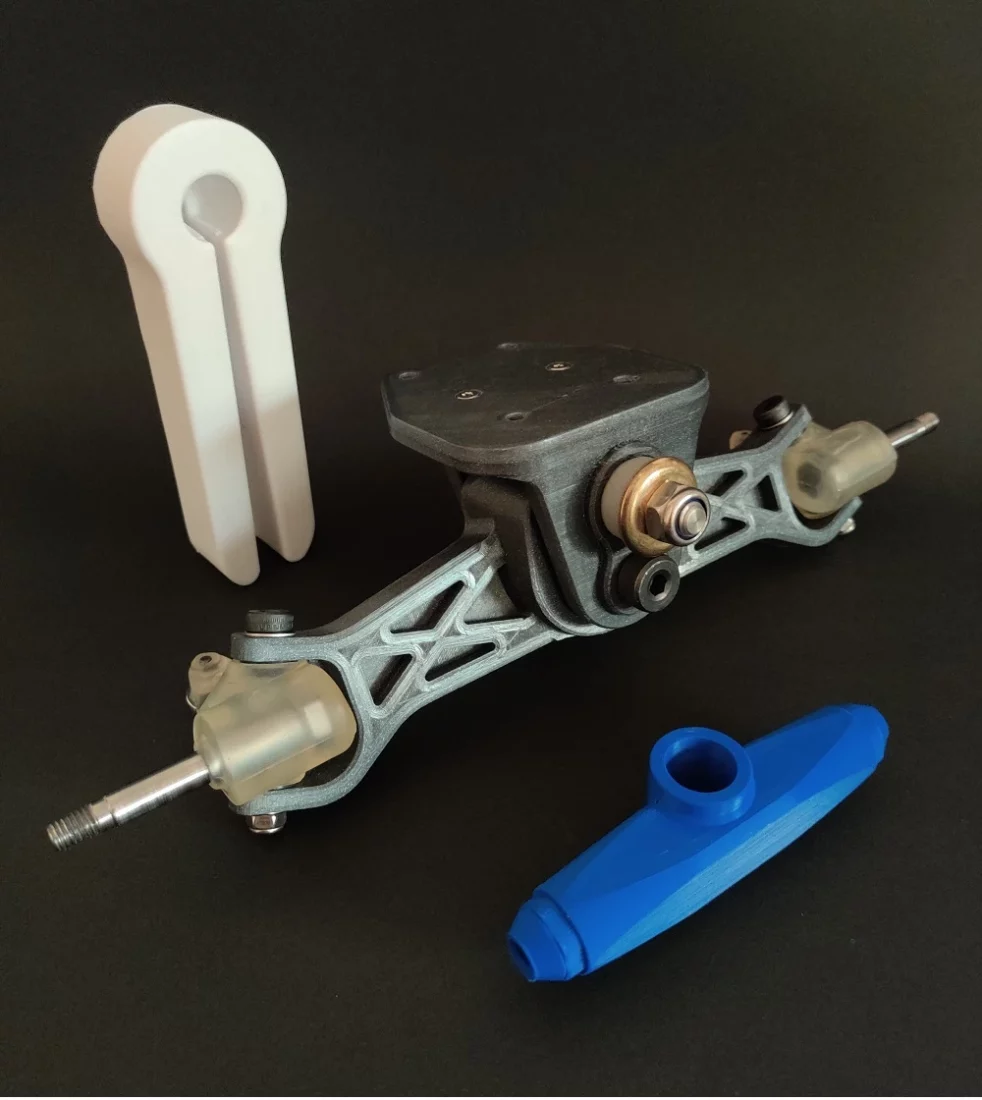

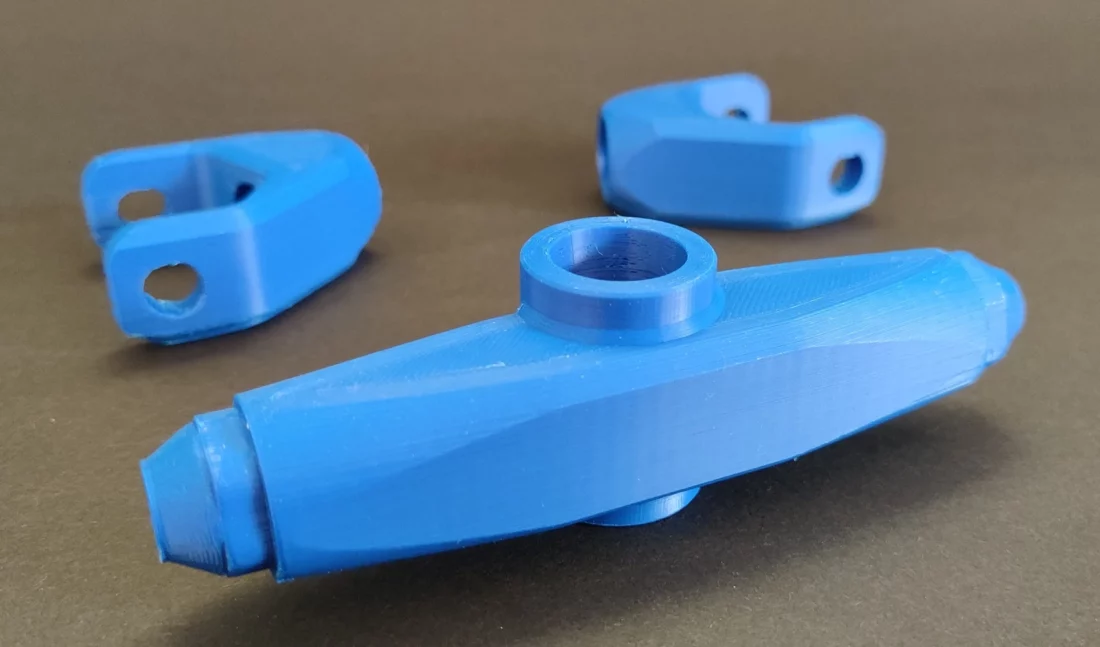

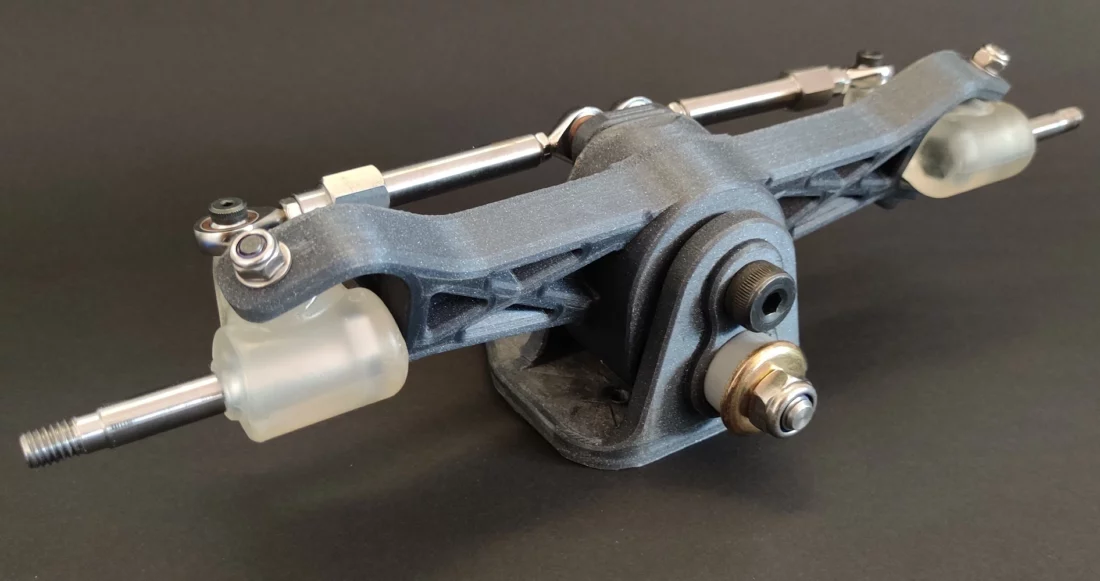

Our FDM 3D Printing Service

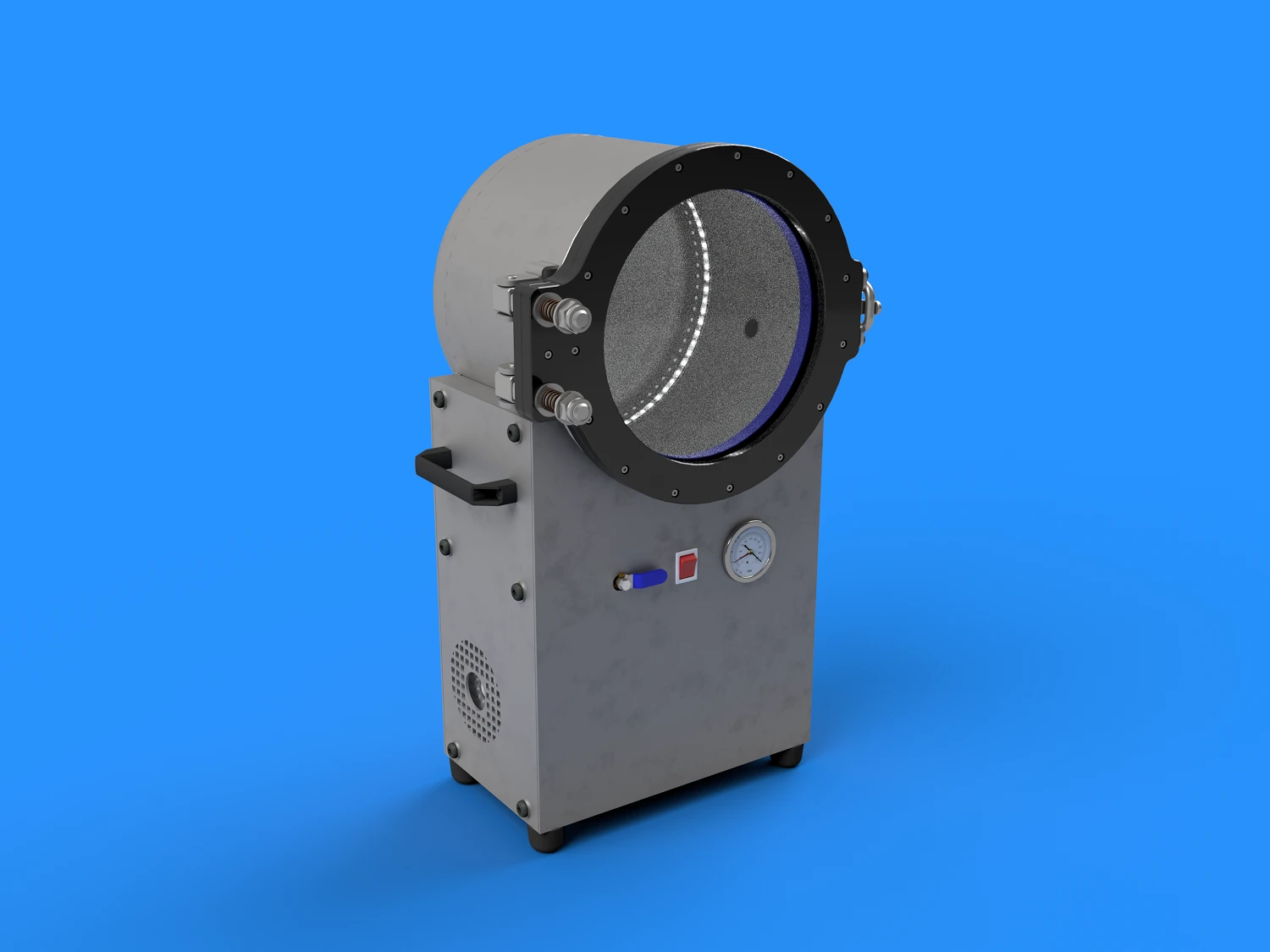

For us to offer Fused Deposition Modeling (FDM)services, we had built a machine park consisting of, among other things, 3D printers made specifically for the company’s needs, which we called YellowPrinterTM. These machines are suitable for materials with low melting temperature such as ABS, ASA, PETG, PCTG, PLA, TPU, PA12, and PP and can provide high-quality parts with excellent repeatability thanks to the use of precise mechanical and electronic components.

YellowPrinterTM uses a heating chamber that allows us to reduce temperature deformations of 3D printed parts and is equipped with high-quality extruders that can feed PA CF (Nylon Carbon Fiber) filament for the parts that require high strength or impact resistance or even flexible materials up to 30 Shore D.

Technical specification

Maximum build dimensions

- Dimensions are unlimited as components may be composed of several sub-parts

- The maximum build envelope is 400 x 400 x 450 mm (in-house), 914 x 610 x 914 mm (outsourced)

Standard accuracy

- ±0.15% (with a lower limit of ±0.2 mm)

Layer thickness

- 50 – 300 μm

Minimum wall thickness

- 1 mm

Surface structure

- Unfinished parts typically have a rough surface but various post-production finishes are possible