Insert molding

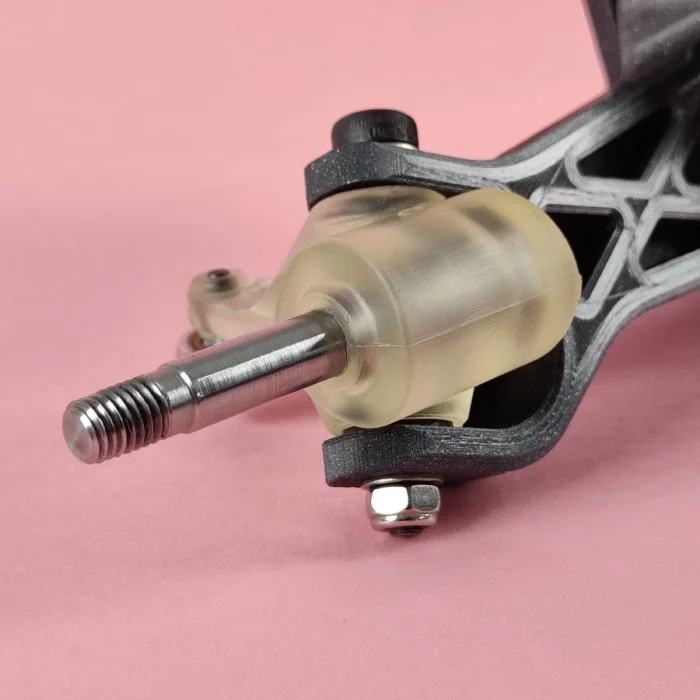

Insert molding is a technique in which plastic is injected into a mold with prepared inserts such as shafts, forming inserts, threaded inserts for injection molding, etc. It is used to produce one piece parts in which a plastic encases a prefabricated part (usually a non-plastic part).

This process is executed by placing the inserts into the molds, then the mold is closed, and two polyurethane compounds are poured into it. The liquid resins are injected into the mold and flow around the captured inserts. The resin then solidifies and sticks tightly to the insert. After the mold is opened, the insert is encapsulated in the plastic part to create a common unit.

The advantages of insert molding include:

- elimination of part assembly,

- improved part reliability,

- enhanced part strength,

- reduced part size and weight.

You do not have to worry about choosing the right material for your prototype. We will do it for you! All you have to do is attach a file with the Technical Data Sheet (TDS) of the material you want your final product to be made of or let us know what environmental conditions it has to withstand. We will select the material that will best reflect the characteristics you want.

If you need design assistance in making your over-molding or insert molding prototype, contact our team. We are always happy to help you with your projects.

Our Overmolding and Insert molding prototyping service

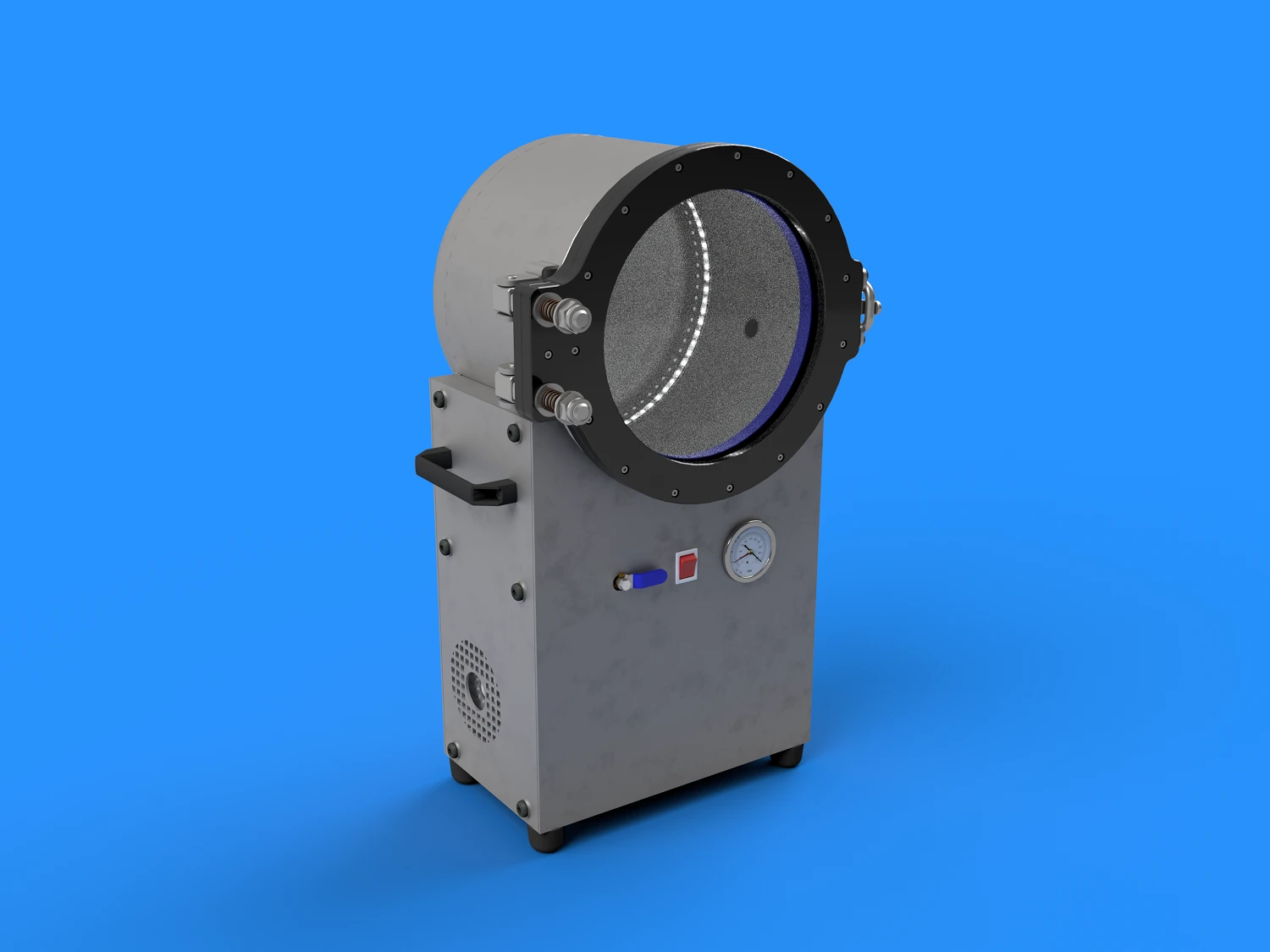

In order to provide Urethane Vacuum Casting Prototyping services, we had built a machine park consisting of 3D printers, low-pressure injection molding machines, and vacuum casting equipment specifically designed to meet our customer’s needs.

You can expect that the prototypes you order will be characterized by high accuracy, repeatability, great surface quality, and isotropy properties.

From a single overmold and insert molding, it is possible to produce even several dozen copies of an element, which additionally allows you to reduce the cost of prototyping, depending on the geometry. Molds can be simple – bipartite – as well as a complex with many dividing lines.

Technical specifications

Maximum build dimensions

- Dimensions are unlimited as components may be composed of several sub-parts

- The maximum 3D printed mold size is 300 x 298 x 164 mm

Standard accuracy

- ±0.2% (with a lower limit of ±0.2 mm)

Mold or 3D printed master pattern layer thickness

Minimum wall thickness

Surface structure

- Finished parts typically have smooth and homogeneous surfaces. Depending on the material, polyurethane dyeing is available