Available materials for CNC milling

While potentially any solid, stable material can be milled, together with our trusted partners we offer you a standard selection of raw materials including:

- hard plastics,

- aluminum,

- wood,

- various types of steels,

- titanium,

- magnesium,

- brass, copper and other alloys commonly used in the prototyping process.

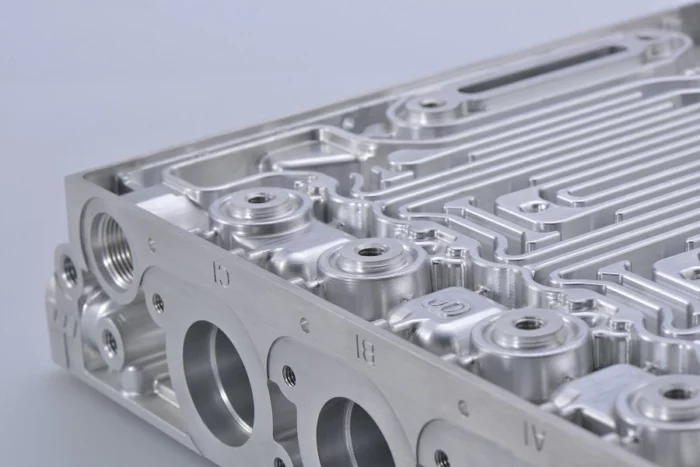

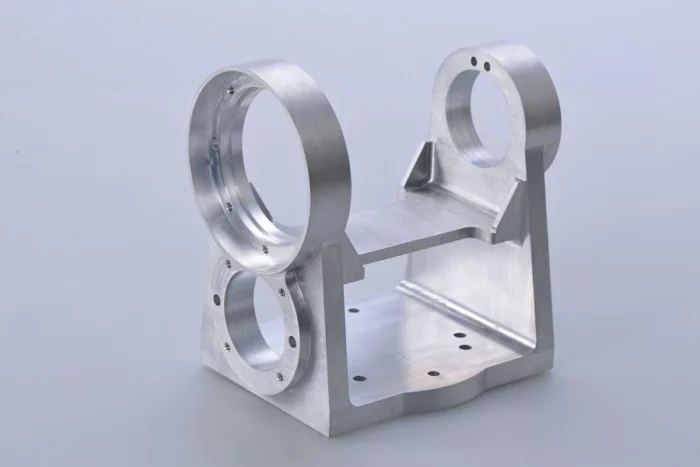

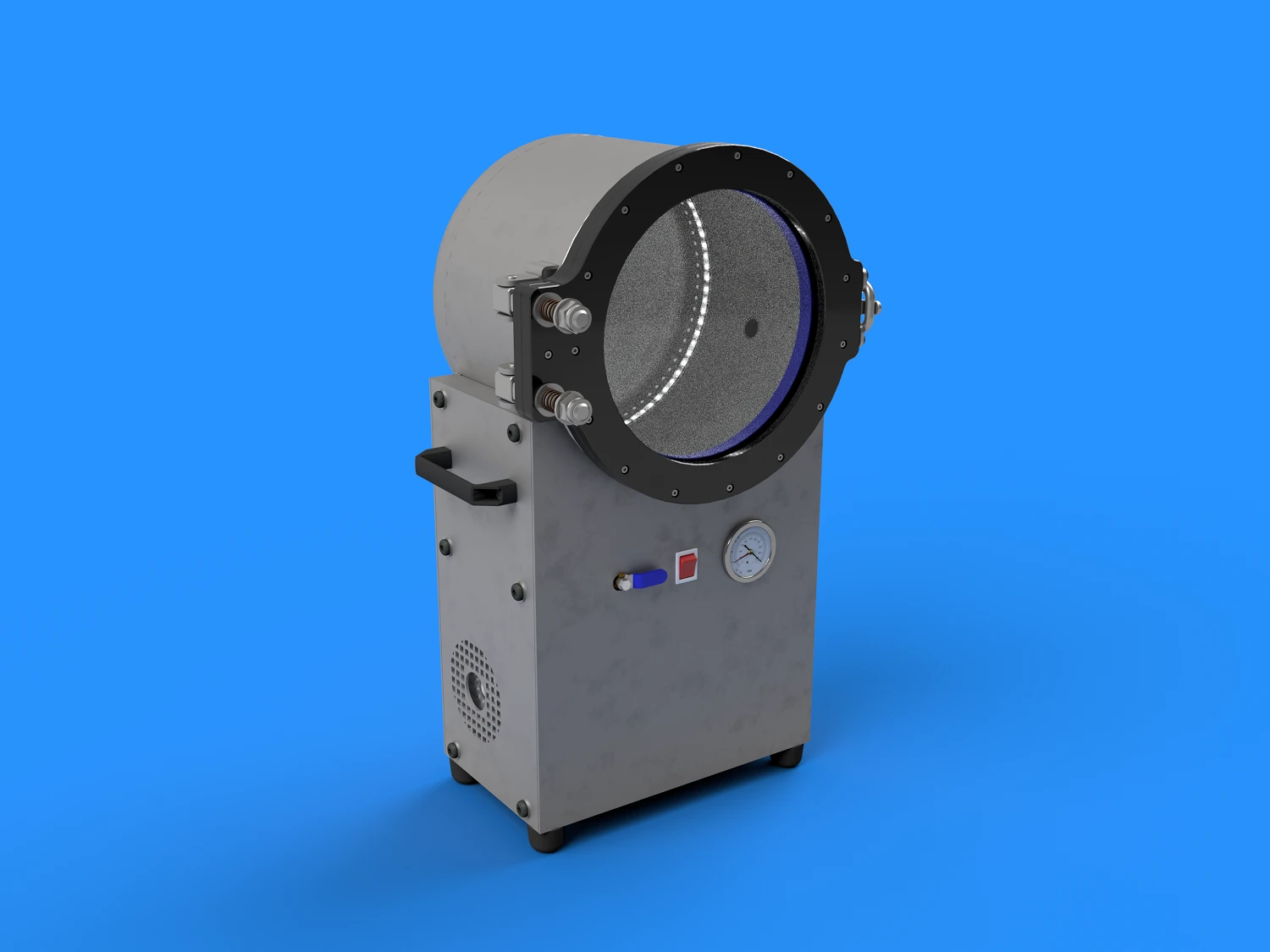

Our company collaborates with trusted partners in the field of 3 axis, 3+2 axis, and full 5-axis milling prototyping which allow you to produce highly accurate and quality parts to meet even your most stringent requirements.