Available materials for CNC turning

While potentially any solid, stable material can be turned, together with our trusted partners we offer a standard selection of raw materials including:

- hard plastics,

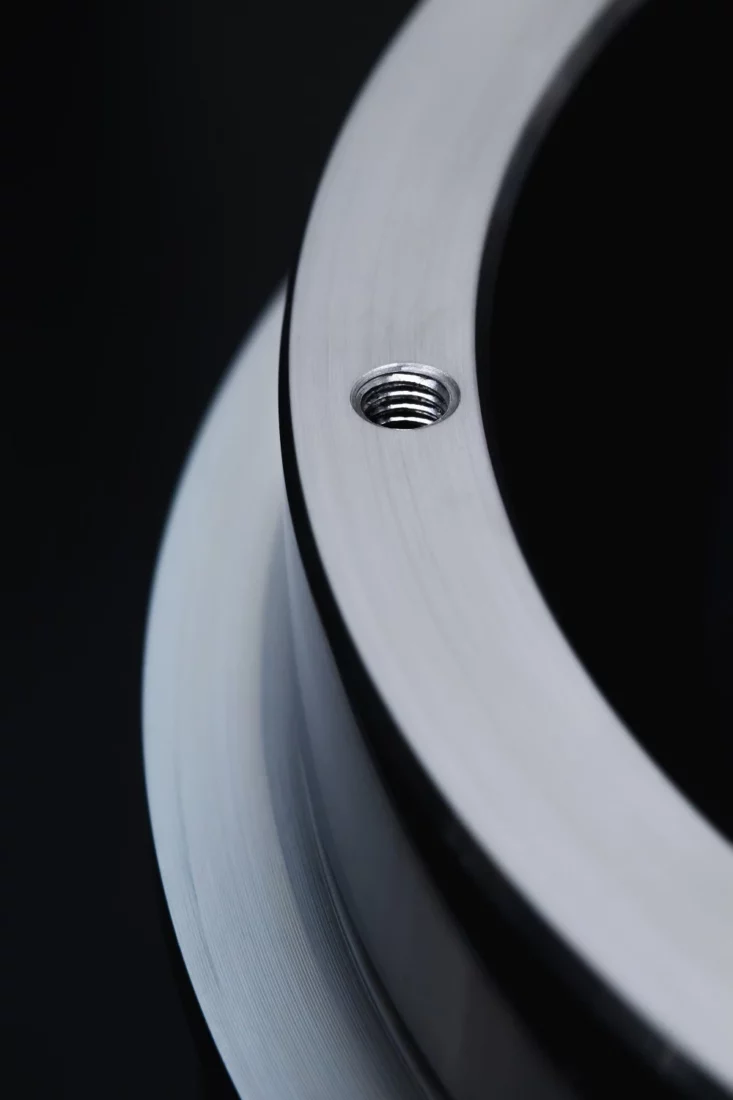

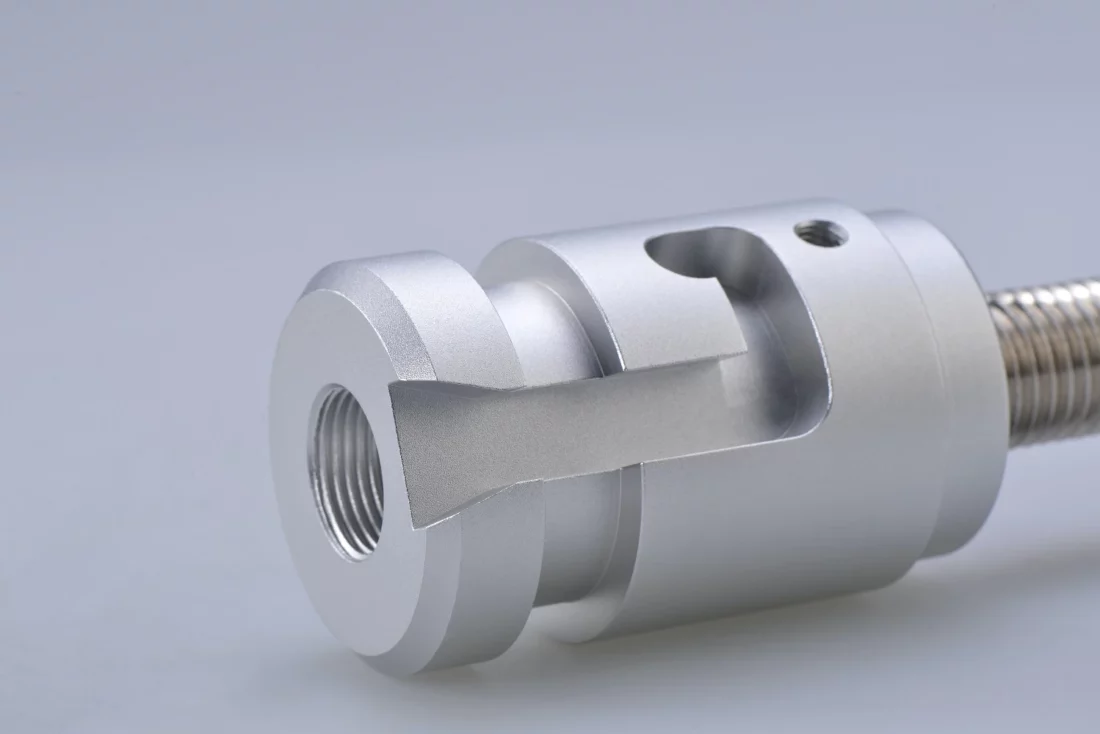

- aluminum,

- wood,

- various types of steels,

- titanium,

- magnesium,

- brass, copper and other alloys commonly used in the prototyping process.

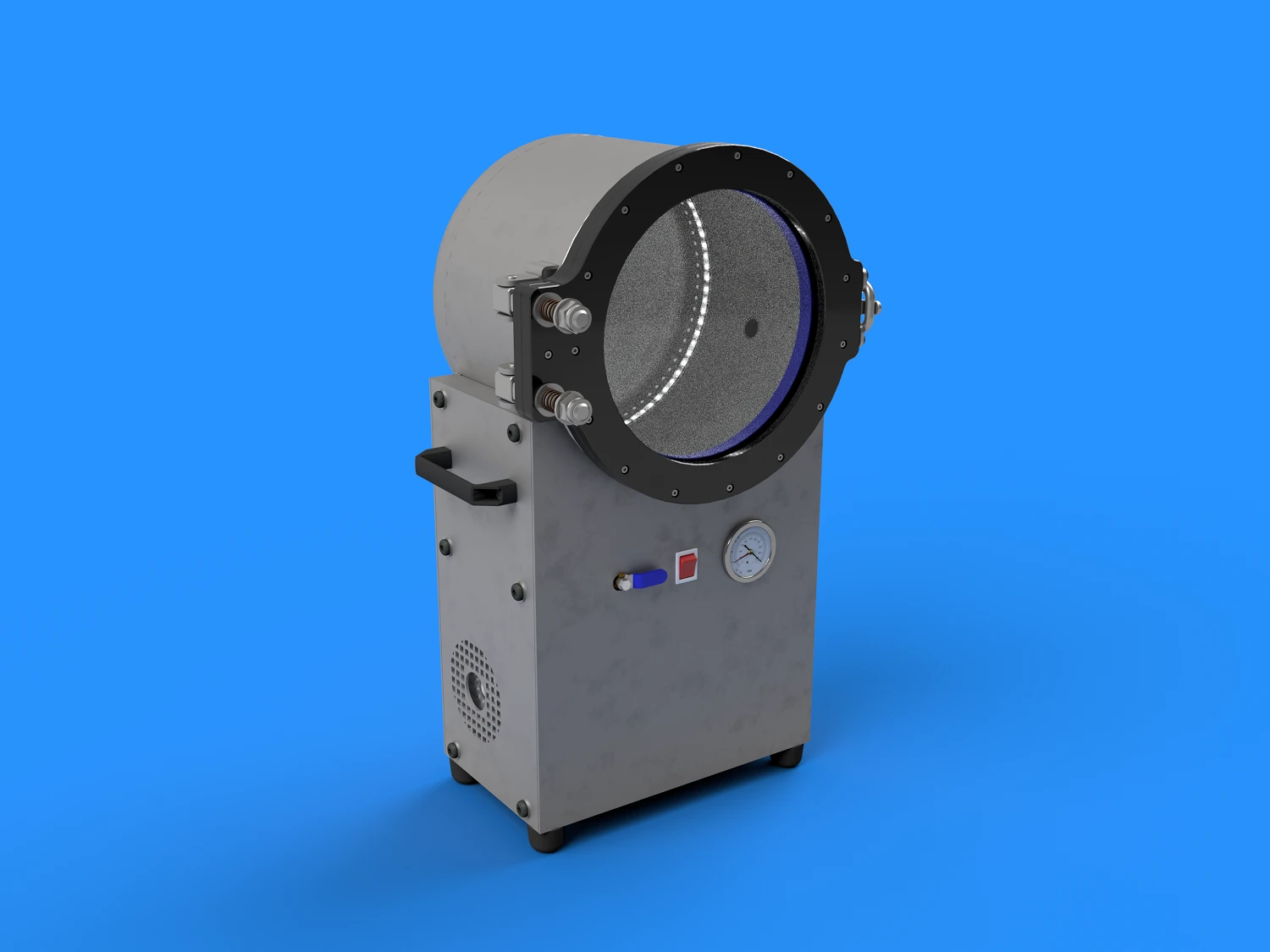

Our company collaborates with trusted partners in the field of CNC turning prototyping, which allows you to produce highly accurate and quality parts to meet even your most specific requirements. Our company has strict NDA agreements with all manufacturing partners. We can provide ISO9001-certified manufacturing partners if required, dimensional inspection reports, and material certification reports on request.

In addition to CNC milling service, we collaborate with trusted partners in additional finishing post-processing services like:

- bead blasting,

- anodizing,

- powder coating,

- electroplating,

- metal brushing.

Technical specifications

Maximum part dimensions

- Maximum part diameter: 431 mm

- Maximum part length: 990 mm

- Maximum swing over the carriage: 350 mm

- Maximum spindle through-hole: 40 mm

Standard accuracy

- ISO 2768 standards (link do guality standard) for CNC Turning

Surface structure

- Various post-production finishes are possible: bead blasting, anodizing, powder coating, electroplating, metal brushing