Available materials for SLA

Our 3D printers enable the rapid exchange of materials in their workspace. This allows us to deliver your prototype in a short time, from a single piece, with material that perfectly suits your needs.

You do not have to worry about choosing the right material for your prototype. We will do it for you! All you have to do is attach a file with the Technical Data Sheet (TDS) of the material you want your final product to be made of or let us know what environmental conditions it has to withstand. We will select the material that will best reflect the characteristics you want.

One of the most important benefits of resin 3D printing is the variety of materials that can be used to create parts for diverse applications. Resins can feature a wide range of formulations: materials can be soft or hard, heavily filled with secondary materials such as glass and ceramics, or have mechanical properties such as high temperature deflection or impact resistance.

Resin 3D prints are isotropic, meaning their properties do not change within the direction of stress. SLA prints can also include an internal infill structure to reduce the weight of the parts or increase strength in certain areas of the part.

Our resin 3D printing service

There are many 3D printing methods on the market, but we choose the best ones for processing each of your orders.

Stereolithography (SLA) and Digital Light Processing (DLP) are the two most common processes for resin 3D printing. In both methods, the liquid is selectively exposed to the light source – SLA a laser, DLP a projector – to form very thin, solid layers of plastic that stack up to form a solid object.

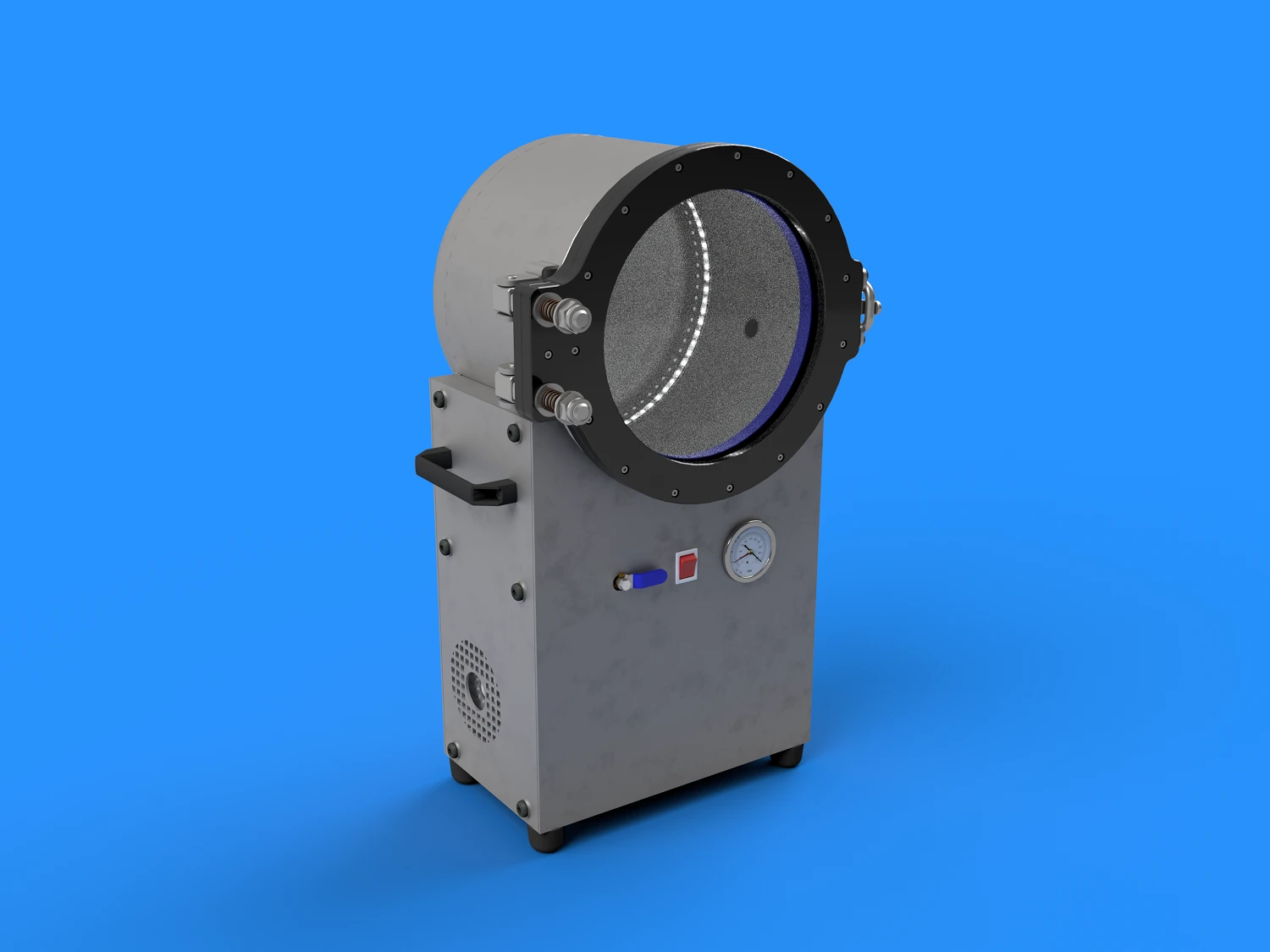

Instead of traditional SLA 3D printers, we use Low Force Stereolithography (LFS) technology, which is the next level of SLA 3D printing which drastically reduces the forces applied on parts during the printing process. It offers you the ability to produce thin-walled parts with minimal support structures and better surface quality.

We offer MSLA (Masked Stereolithography) 3D printing service for larger parts that require high accuracy level or special material properties that cannot be achieved on traditional FDM machines.

You can choose DLP (Digital Light Processing) technology to produce small and highly accurate parts with complex surface textures.

Technical specifications

Maximum build dimensions

- Dimensions are unlimited as components may be composed of several sub-parts

- The maximum build envelope is 300 x 298 x 164 mm (in-house), 1100 x 690 x 590 mm (outsourced)

Standard accuracy

- ±0.2% (with a lower limit of ±0.15 mm)

Layer thickness

- 25 – 200 μm

Minimum wall thickness

- 0,4 mm

Surface structure

- Unfinished parts typically have a smooth surface with low visible building layers. Sometimes they have supports marks on the surface. Various post-production finishes are possible