You can contact our team for specific calculations related to your project. At the end of the work, you will receive a professional analysis report that allows you to improve your product.

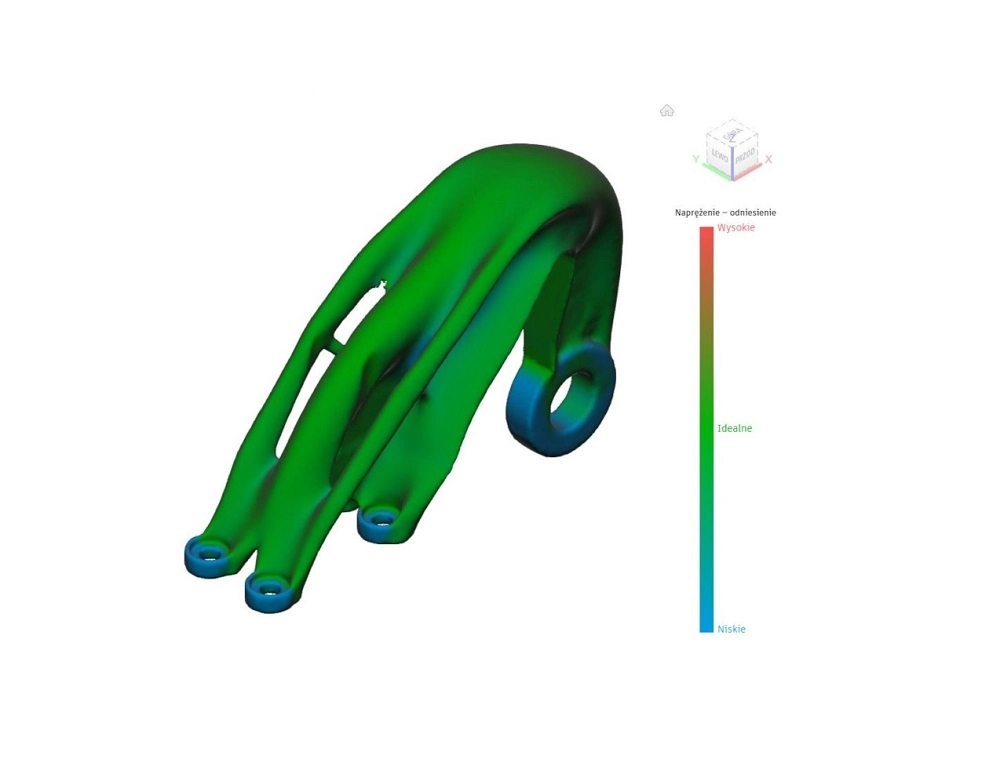

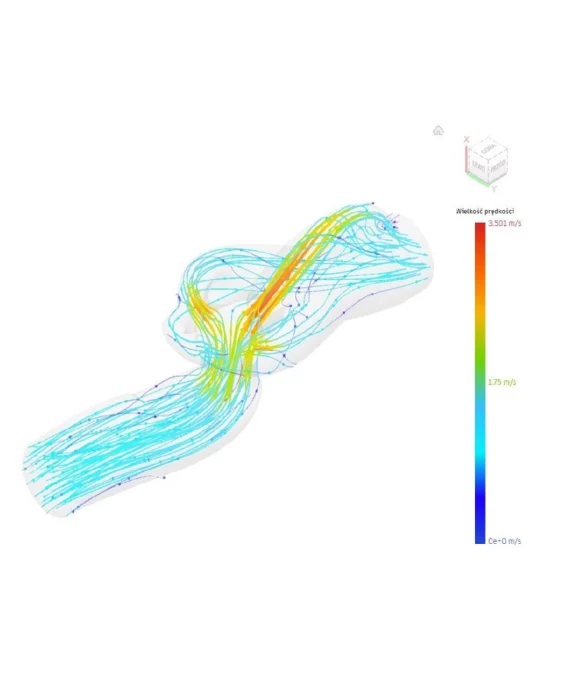

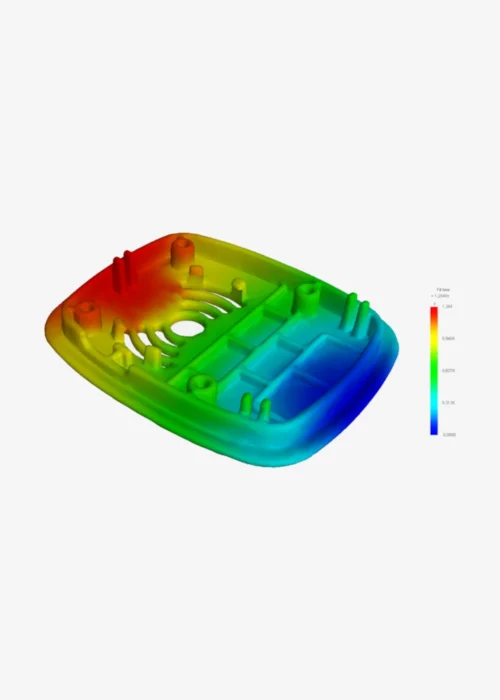

FEA works by breaking down a real object into numerous finite elements, such as small tetrahedrons. Mathematical equations help predict the behavior of each small element, and thanks to professional software we are capable of predicting the behavior of the real object by summing up those results.

Our company can help you perform analyses: mechanical stress, mechanical vibration and preview of electronics cooling.