Yellowhammer

We turn clients’ visions into reality

Our company offers services in the field of concept & product design as well as high-end prototyping.

- Unique prototyping techniques

- Lead times from 1 working day

- Experienced R&D department

Modern design and attention to details

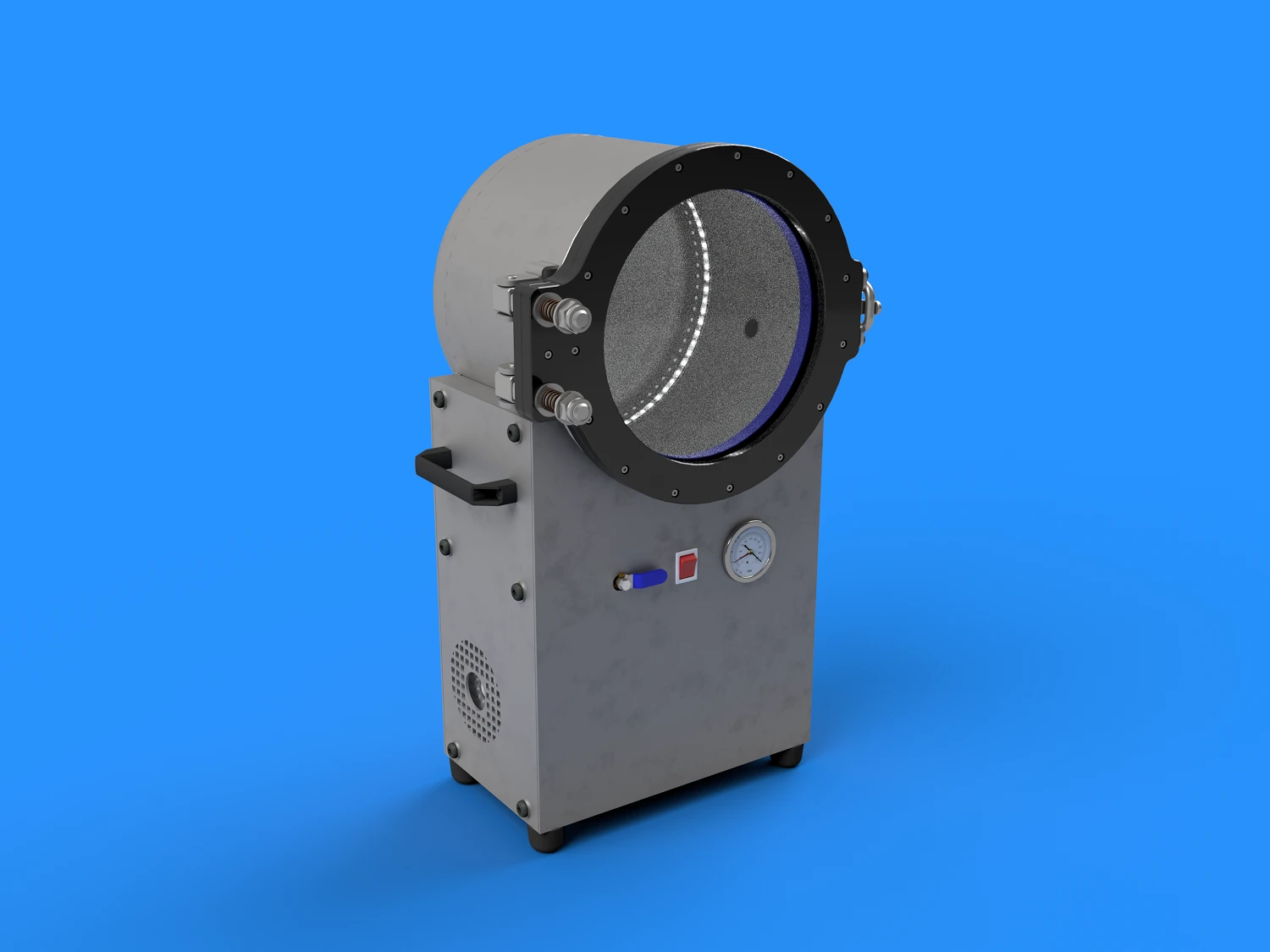

We have experience in the development of machines and their components, electronic devices, and tools that meet the requirements of our clients.

- Wearable & Consumer Electronic Devices

- Machines components

- Manufacturing & prototyping devices

- Micromobility & automotive

Products that meet your requirements

Our team will help you choose the appropriate prototyping technique for your needs. We also offer those developed specifically in our R&D department.

- 3D Printing

- Low-Pressure Injection Molding & Vacuum Casting

- Metal Machining

Design, prototyping, testing and production

You can contact our team to bring your products to life, no matter how far you are in the process.

Using the highest-class technologies of additive manufacturing, low-pressure plastic injection, vacuum casting, machining and sheet metal processing, our company will help you create your product or its prototype.

Yellowhammer consists of design, simulation, prototyping and production specialists who are happy to help you and your company at any time.

Product development

Comprehensive support for mechanical and electronic design, prototyping, certification, and production management. Reduce lead time and ensure that every aspect of the project is carefully thought out.

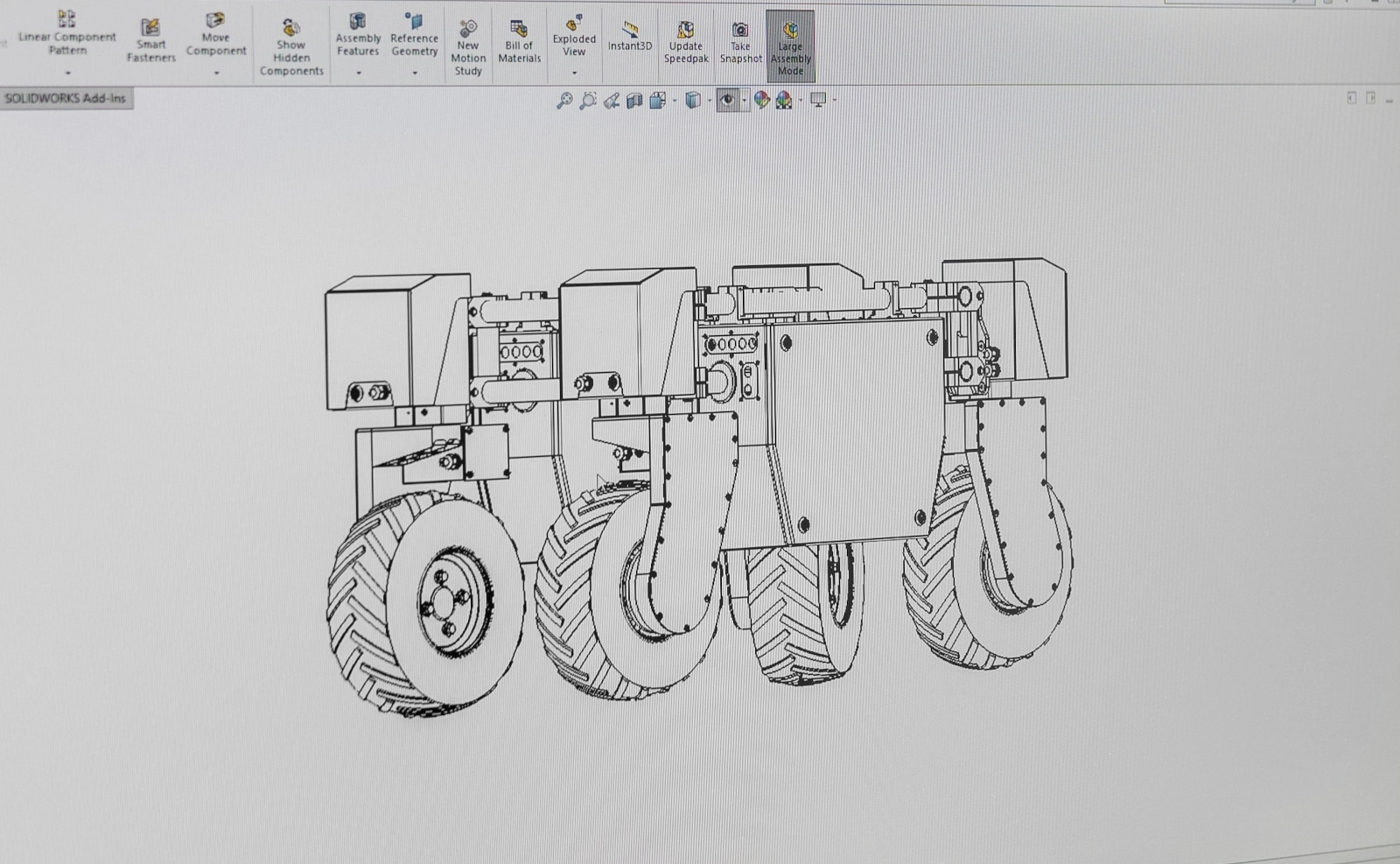

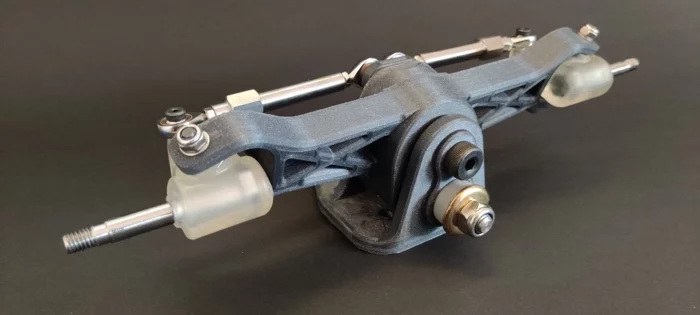

Mechanical design

Support for mechanical and mechatronic projects using the newest technologies in 3D design and rapid prototyping. In-house prototyping radically reduces time and cost of project development.

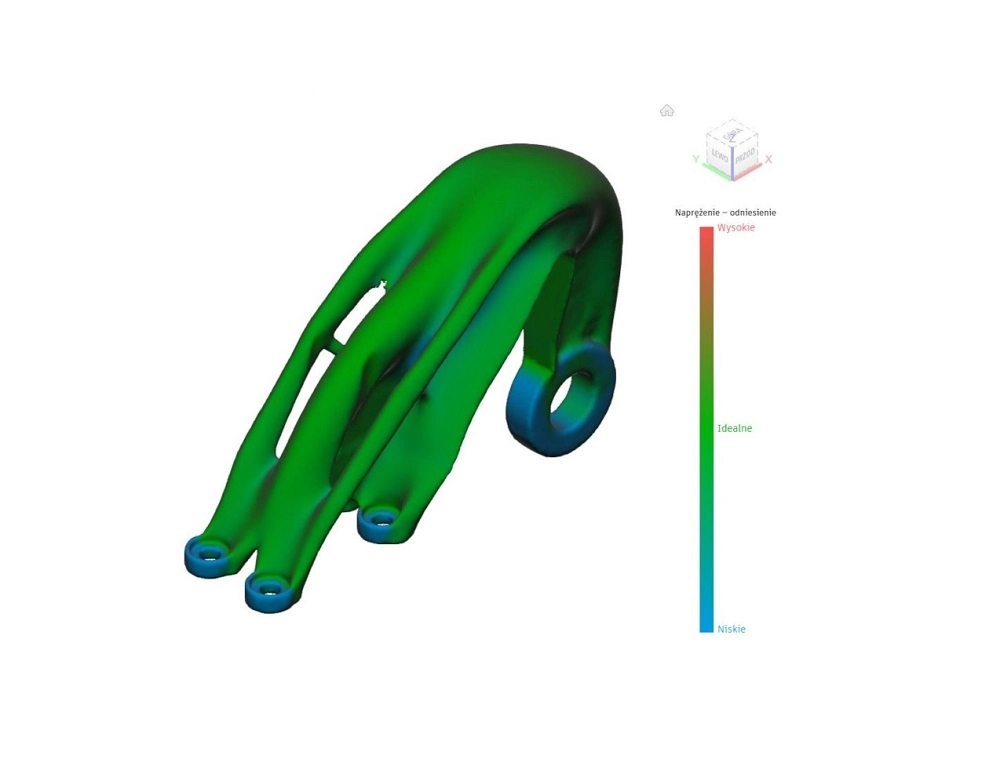

Engineering analysis and FEM Simulations

Professional Finite Element Analysis (FEA) service using the latest technologies in computer design. Generative design service for additive manufacturing.

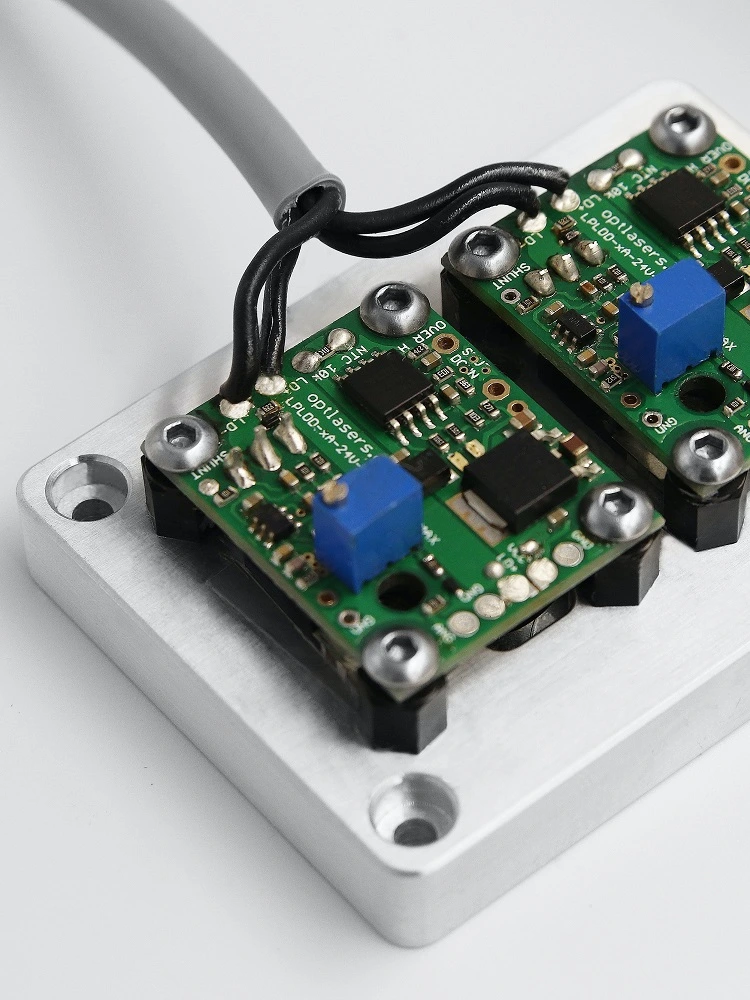

Electronics design

We design customized solutions for consumer electronics and integrated circuits for machines.The optimal design guarantees high reliability at a reasonable price.

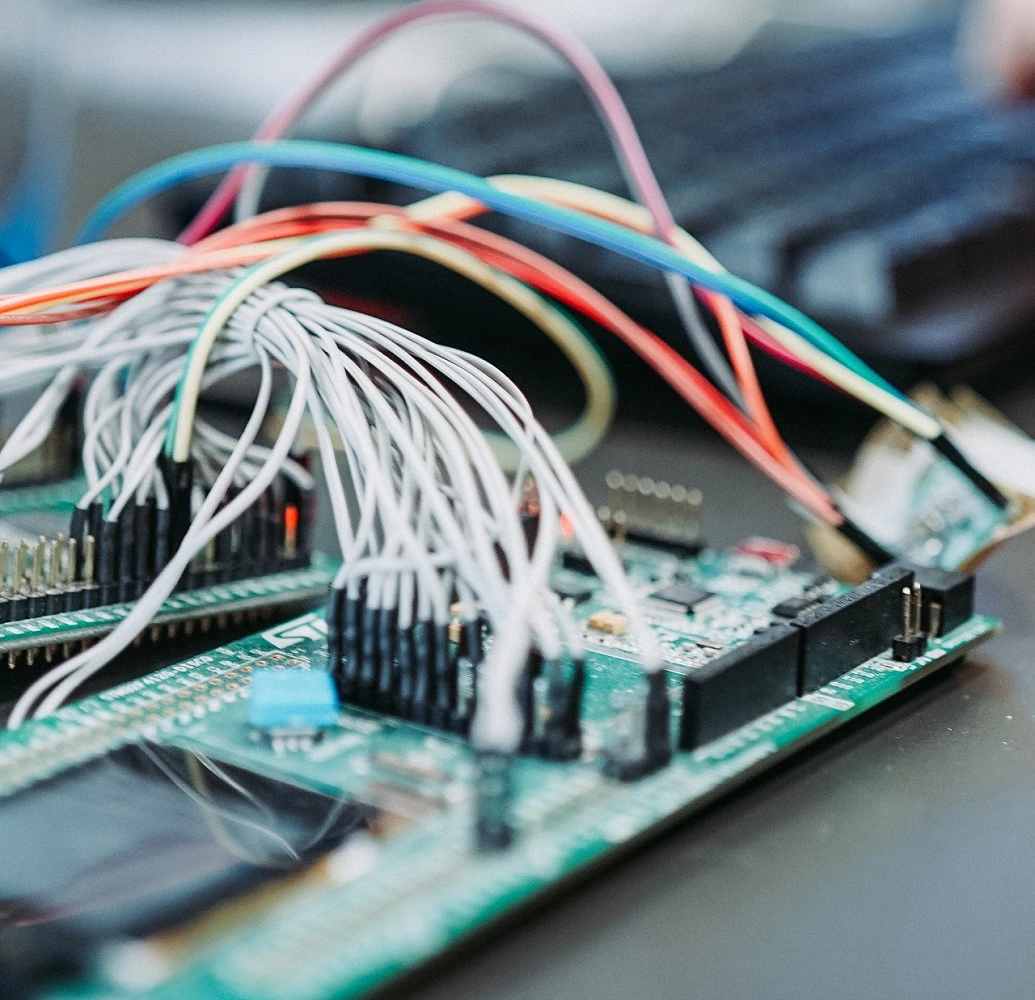

Embedded software development

Programming of microcontroller service for consumer electronics and wearable devices. Software design based on proven and reliable solutions as well as new market trends.

SLA, LFS & DLP

Parts with smooth surfaces, high dimensional accuracy, and large build volume.

- Dimensional accuracy from ± 0.2% with a lower limit of ± 0.15 mm

- Maximum part dimensions up to 1100 x 690 x 590 mm

SLS & MJF

Isotropic mechanical properties and no visible support structures.

- Dimensional accuracy from ± 0.3% with a lower limit of ± 0.3 mm

- Maximum part dimensions up to 630 x 330 x 550 mm

FDM

Wide range of materials and colors for affordable prototyping.

- Dimensional accuracy of ±0.2% (with a lower limit on ±0.2 mm)

- Maximum part dimensions up to 406 x 355 x 406 mm

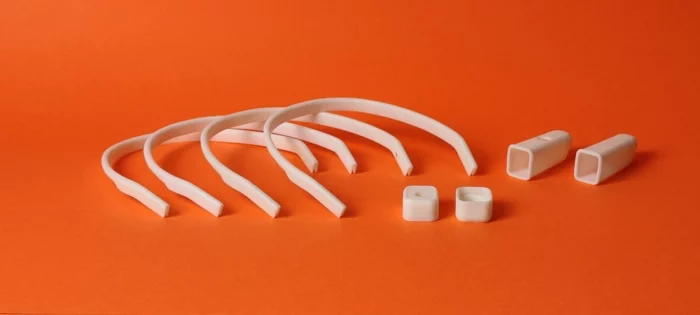

Silicone injection molding

Flexible elements perfectly reflect the characteristics of the production details.

- Dimensional accuracy from ± 0.2% with a lower limit of ± 0.2 mm

- Wide range of materials from 10 – 70 Shore A

Urethane vacuum casting

Rigid and flexible elements that can mimic production materials properties.

- Dimensional accuracy from ± 0.3% with a lower limit of ± 0.3 mm

- Wide range of materials 30 – 95 Shore A and 67 – 86 Shore D

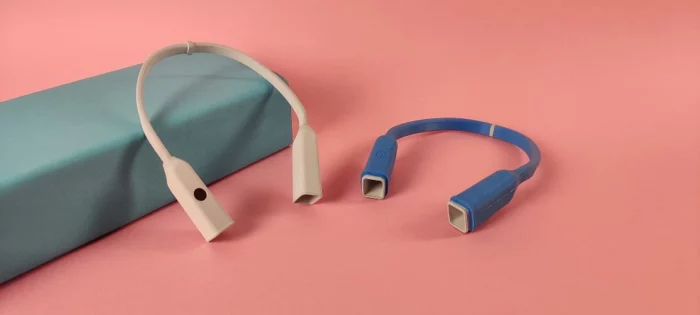

Overmolding & insert molding

Flexible and rigid structures combined with one or more components.

- Soft and watertight surfaces on electronic devices

- Rigid structures with metal inserts

3 & 5 axis CNC milling

Highest part accuracy and a wide variety of materials.

- Dimensional accuracy complies with ISO 2768 standards with a lower limit of ± 50μm

- Wide range of surface treatments: anodizing, galvanization, laser engraving

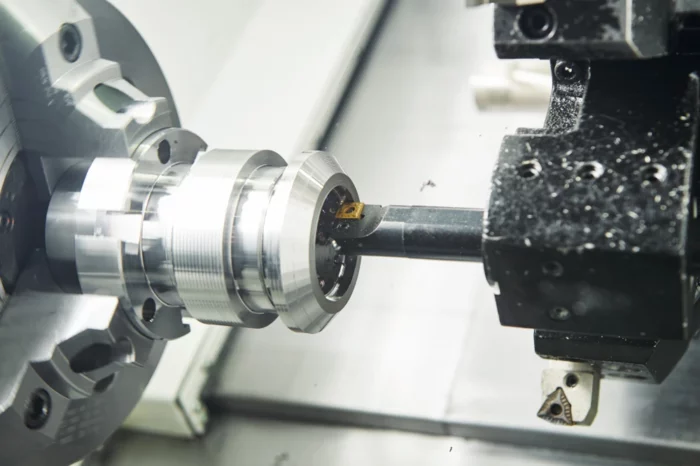

CNC turning

Low-cost parts for simple cylindrical geometries.

- Dimensional accuracy complies with ISO 2768 standards with a lower limit of ± 50μm

- Wide range of surface treatments: anodizing, galvanization, laser engraving

Sheet metal fabrication

Simple and affordable process for metal fabrication.

- Dimensional accuracy complies with ISO 2768 standards with a lower limit of ± 0,2mm

- Laser & waterjet cutting, bending, and post-processing

Low-pressure injection molding and vacuum casting

Precise prototyping of flexible and rigid elements, using 3D printed forms, allowing the mapping of the properties of production materials at low cost and in a short time.

Contact us if you are looking for a method to create prototypes of elements whose operation will reflect the behavior of details in later production.

With this method, you can produce high-quality prototypes of:

- gaskets & O-rings,

- dampers & handles,

- structures with inserts,

- overmolded surfaces,

- and much more…

Our portfolio

We develop products and produce rapid prototypes for customers in various industries: consumer & wearable electronics, food processing, micromobility, automotive, medical devices, hardware startups, and prototyping.

Tell us about your project and get a quote

Our team of experts will help you implement your project quickly and smoothly. Fill out the form and get a free quote and tips on implementing the project.